Internally Threaded

-(1000-x-800-px)-(1).jpg?v=0)

Internally Threaded Elephant Attachment

Internally Threaded Elephant Attachment

-

Size: 5.8mm x 5.1mm

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

24kt Gold PVD Titanium Internally Threaded Square Jewel Attachment

24kt Gold PVD Titanium Internally Threaded Square Jewel Attachment 0.9mm (16G)

- Size: 4.8mm x 7.6mm

Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

Internally Threaded Jewel Dinosaur Attachment

Internally Threaded Jewel Dinosaur Attachment

-

Size: 9.5mm x 5.3mm

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

24kt Gold PVD Titanium Internally Threaded Small Tear Navel

24kt Gold PVD Titanium Internally Threaded Small Tear Navel 1.6mm x 10.5mm

Internally Threaded Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

24kt Gold PVD Titanium Internally Threaded Bezel Set - Mini Navel

24kt Gold PVD Titanium Internally Threaded Bezel Set - Mini Navel

1.6mm x 10mm - 4mm x 6mm Stones

Internally Threaded Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

Internally Threaded Navel Bar Double Jeweled Swarovski Crystal

Internally Threaded Navel Bar Double Jeweled Swarovski Crystal

Internally Threaded Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

24kt Gold PVD Titanium Prong Set - Mini Navel

24kt Gold PVD Titanium Prong Set Mini Navel

1.6mm x 10mm - 4mm x 6mm Stones

Internally Threaded Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

Internally Threaded Mini Prong Set Navel

Internally Threaded Mini Prong Set Navel

Internally Threaded Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

Internally Threaded 0.9mm (Bottom) and Threadless (Top) Navel Bar

Internally Threaded 0.9mm (Bottom) and Threadless (Top) Navel Bar

1.6mm (14g) x 10mm

Internally Threaded Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

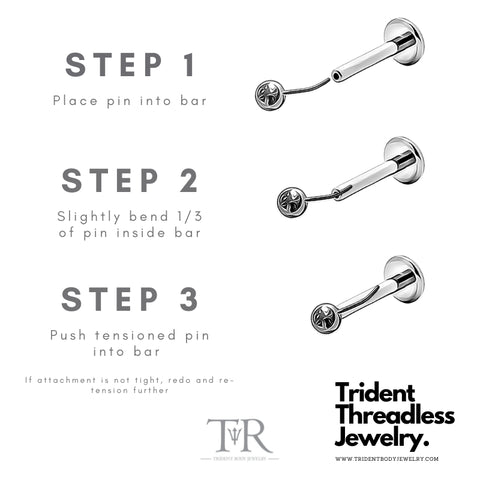

Threadless Jewelry Method:

Threadless jewelry is tensioned by using the end of the attachment and bending it within the bar to hold into place. To create the tension insert the pin on the end of the attachment slightly into the bar and bend slightly. Once inserted into the bar the bend in the pin should create the tension needed to hold into place. Direction below:

- Insert the pin on the end of the attachment 1/4 - 1/3 into the bar. (Labret, barbell etc.)

- Slightly bend the insertion pin within the bar.

- Push the end into the shaft and test the fit.

Insuring the fit: Insure the attachment is held in place and is tight. Adjust as necessary, if the pin does not hold tight enough redo the steps & create more tension.

24kt Gold PVD Titanium Internally Threaded Bee Attachment

24kt Gold PVD Titanium Internally Threaded Bee Attachment 0.9mm (16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

Internally Threaded Bee Attachment

Internally Threaded Bee Attachment

Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

Internally Threaded Moon with Opal Attachment

Internally Threaded Moon with Opal Attachment

Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

Internally Threaded Small Mix Color Flower Attachment

Internally Threaded Small Mix Color Flower Attachment 0.9mm Thread (For 16G)

Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

Internally Threaded Disk Attachment

Internally Threaded Disk Attachment 0.9mm (For 16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

Internally Threaded Spike Attachment

Internally Threaded Spike 3mm Attachment 0.9mm (For 16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

Internally Threaded Sword Attachment

Internally Threaded Sword Attachment 0.9mm (For 16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

24kt Gold PVD Titanium Internally Threaded 10 Petal Jeweled Flower Attachment

24kt Gold PVD Titanium Internally Threaded 10 Petal Jeweled Flower Attachment 0.9mm (16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

24kt Gold PVD Titanium Internally Threaded Moon Attachment

24kt Gold PVD Titanium Internally Threaded Moon Attachment 0.9mm (16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

Internally Threaded Jeweled Ovate Flower Attachment

Trident Titanium Internally Threaded Jeweled Ovate Flower Attachment 0.9mm (For 16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

24kt Gold PVD Titanium Internally Threaded Labret Pin

24kt Gold PVD Titanium Internally Threaded Labret Pin

16GA / 1.2mm - 3mm Base

16GA / 1.2mm - 4mm Base

Internally Threaded Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

Internally Threaded Marquise With Round Stone Navel

Trident Internally Threaded Marquise Round Stone Navel 1.6mm x 10mm

Internally Threaded Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

Internally Threaded Small Tear Navel

Internally Threaded Small Tear Navel 1.6mm x 10.5mm

Internally Threaded Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

24kt Gold PVD Titanium Internally Threaded Jeweled 5 Stone Bar Attachment

24kt Gold PVD Titanium Internally Threaded Jeweled 5 Stone Bar Attachment 0.9mm (16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

24kt Gold PVD Titanium Internally Threaded 5 Curved Jeweled Prong Set Attachment

24kt Gold PVD Titanium Internally Threaded 5 Curved Jeweled Prong Set Attachment 0.9mm (16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

24kt Gold PVD Titanium Internally Threaded Trio Attachment

24kt Gold PVD Titanium Internally Threaded Trio Attachment 0.9mm (16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

24kt Gold PVD Titanium Internally Threaded Claw Set Attachment

24kt Gold PVD Titanium Internally Threaded Claw Set Attachment 0.9mm (16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

24kt Gold PVD Titanium Internally Threaded Jeweled Internal Flat Attachment

24kt Gold PVD Titanium Internally Threaded Jeweled Internal Flat Attachment 0.9mm (16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

24kt Gold PVD Titanium Internally Threaded Jeweled 4 Stones Attachment

24kt Gold PVD Titanium Internally Threaded Jeweled 4 Stones Attachment 0.9mm (16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

Internally Threaded Titanium Dangle Navel Bar

Internally Threaded Dangle Navel Bar 1.6mm x 10mm

Internally Threaded Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

24kt Gold PVD Titanium Internally Threaded Lightning Bolt Attachment

24kt Gold PVD Titanium Internally Threaded Lightning Bolt Attachment 0.9mm (16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

24kt Gold PVD Titanium Internally Threaded Long 3 Jewel Attachment

24kt Gold PVD Titanium Internally Threaded Lab Cluster Long 3 Jewel Attachment 0.9mm (16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)

PVD (Vacuum coating), also known as thin-film deposition, is a vacuum chamber process whereby a very thin and steady layer of coating is applied to the titanium surface of a substrate, protecting it from forces that might wear it down or decrease its efficiency.

PVD Coating isn’t adding another layer to the object that will chip or crack with time (think old paint).

PVD coating is becoming a standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antimicrobial, and it serves as a chemical barrier for those with a sensitivity to nickel (which can often be found in the tool).

As opposed to other coatings that chip, crack, and wear down, vacuum coatings are a shining armor for your jewelry, providing a strong and thin coating for a variety of applications.

Unlike paints which other companies use and many other methods, this technique is body-friendly so it can be used safely and without a problem.

Internally Threaded Jeweled Tear Cluster Attachment

Internally Threaded Tear Cluster Attachment 0.9mm (For 16G)

Internally Threaded Titanium Manufactured out of Implant Grade Titanium (Ti-6AL-4V-ELI ASTM F136)